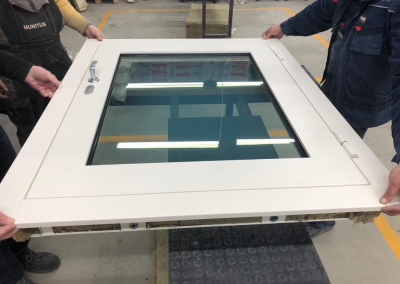

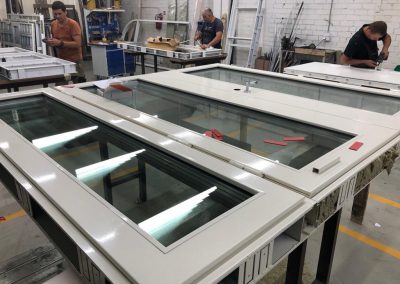

Assembly shop

Assembly shop is where the robust metal construction of the door or window unites with beautiful custom made finishing panels, security locking systems and other hardware into a complete package. Our highly skilled employees with long experience assembling custom security doors, with electronic lock systems can handle this job efficiently.

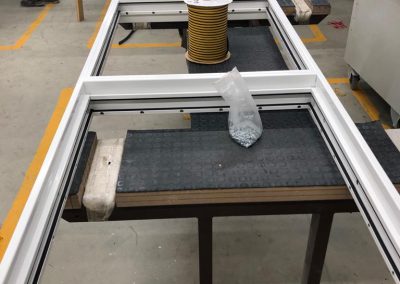

Packing and shipping

We are packing our products for shipping in such manner following where and how they are being shipped. For air cargo or ocean ships, we pack Munitus security products in individual reinforced boxes. For shorter deliveries, we use more straightforward boxes. If the doors are without glasses, we pack them into corrugated cardboard or the simplest packing is on the pallets one by one and protects them with PVC film and pallets additionally packed with corrugated cardboard.